ODM/JDM Manufacturing Service Overview

Optics, Laser Module, Laser Sensor, Camera Module, Machine Vision, Robot Sensor, Optoelectronic Solutions, AISOC Edge Computing for AI Vision and Robot Application

Leveraging its experience in optics, mechanics, thermal transfer, and electronics, IADIY develops core robotic technologies such as human-robot interaction, motion control, intelligent recognition, sensor fusion, and navigation, providing comprehensive intelligent commercial robot solutions. Currently, its primary focus is on the R&D, manufacturing, sales, and service of intelligent autonomous security drones. We offer Original Design Manufacturing (ODM) and Joint Design Manufacturing (JDM) services, encompassing system specification design, software design, manufacturing, testing and verification, overall solutions, and after-sales service, aiming to fully meet customer expectations and requirements and satisfy the needs of various application fields. In the future, we will further integrate robotics technology to expand into artificial intelligence, the Internet of Things, and other fields, developing intelligent robots/drones to create unique application value in response to various industrial application needs.

IADIY specializes in optoelectronic integration and AISOC application design and manufacturing services. In addition to various embedded computer OBM standard products and ODM manufacturing services, we are also adept at Original Design Manufacturing (ODM), Joint Design Manufacturing (JDM), and Design-In fully customized design services, including motherboard/system specification design, software/firmware design, assembly and manufacturing, design verification, and after-sales service. This ensures we fully meet customer expectations and requirements, satisfying the application needs of various fields such as edge computing, AIoT, smart retail, industrial automation, smart transportation, healthcare, and network communications. Headquartered in Taiwan, IADIY has three manufacturing bases globally—Zhuhai, China; Osaka, Japan; and Taiwan—implementing strict quality control to supply high-quality optoelectronic products. We possess well-trained R&D personnel, experienced project managers, a comprehensive manufacturing system, and an after-sales service system, enabling us to fully realize the design and manufacturing needs derived from customers' initial concepts, producing high-quality customized products that perfectly meet their requirements.

Since its establishment in 2006, we have fully leveraged our mature design and manufacturing advantages to assist customers in successfully applying customized embedded computer control boards, embedded computer systems, touch screen computers, tablet computers, and network communication products to various large-scale customized projects. These include AI-powered smart industrial robots, AMR autonomous mobile robots, smart battery swapping stations, smart charging piles, and smart parking pillar manufacturing services; drive-through car ordering systems; smart scoreboards; POS systems; smart potato sorting machines; bedside medical care and entertainment systems; and outdoor handheld tablet computers. Furthermore, our network communication equipment has been deployed in various enterprise firewalls and industrial manufacturing network security servers, providing enterprises with robust network security protection and assurance. Click the following introduction to learn more about IADIY's innovative technologies and superior design capabilities:

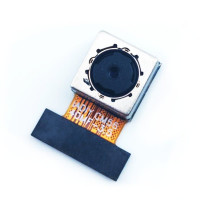

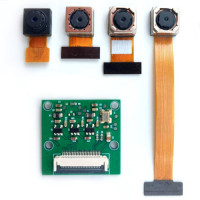

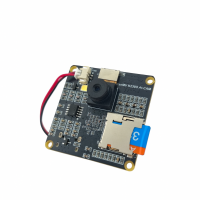

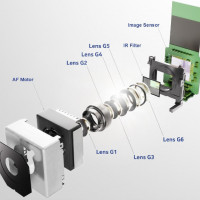

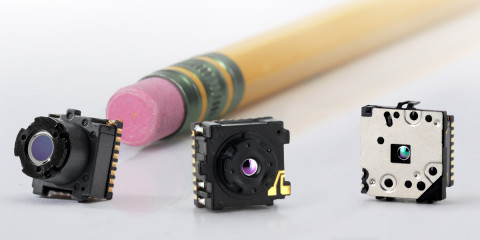

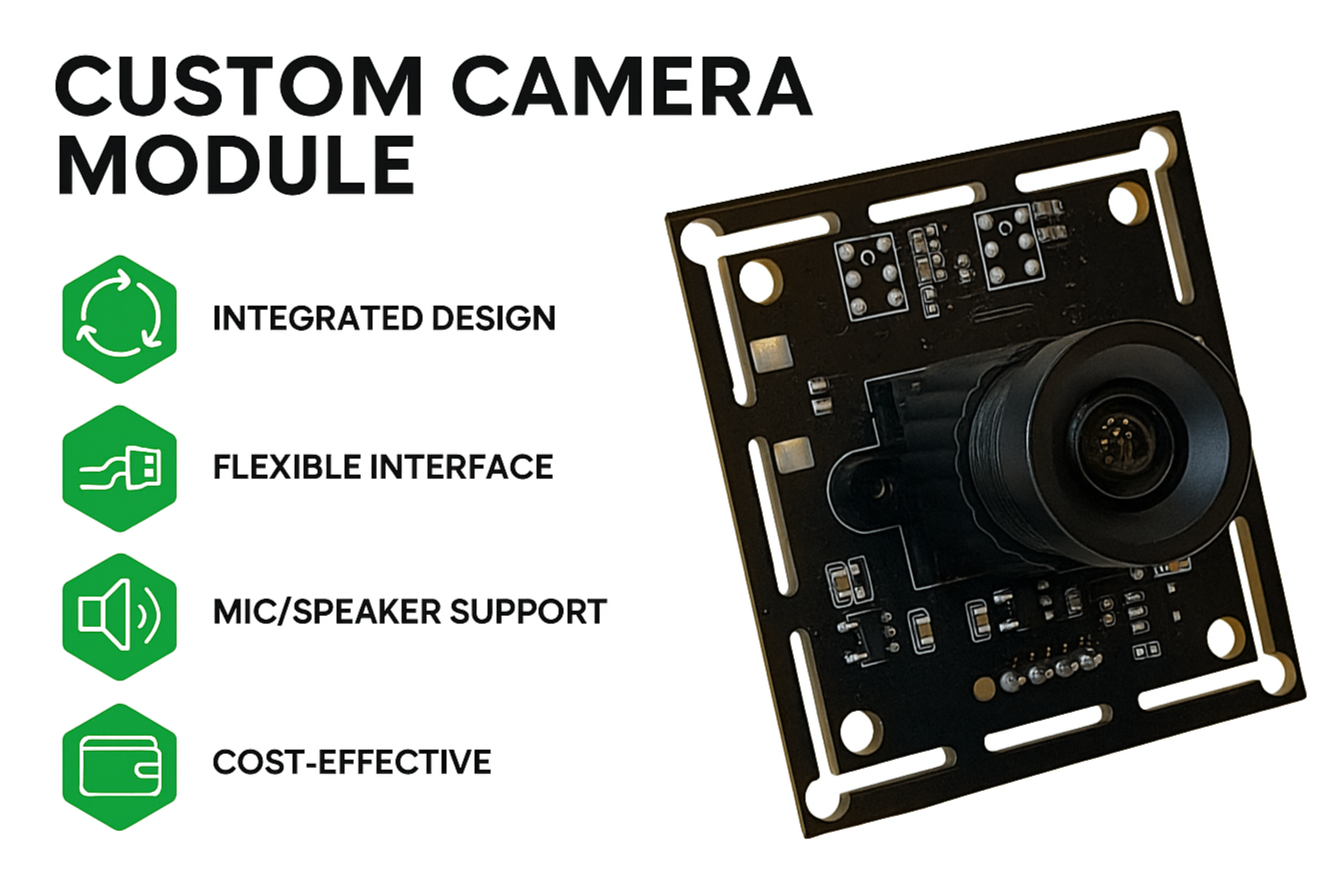

Custom Camera Module Design and Integration

Your Guide to Board Camera Customization and Optimization

Whether you're building a smart device, industrial machine, or medical equipment, the right camera module can greatly enhance product performance. This guide walks you through the key factors and processes in customizing your own camera modules.

1. Define Your Requirements

- Lens Type: Fixed-focus, autofocus, or manual.

- Sensor: CMOS/CCD based on image quality, price, and availability.

- Interface: USB, MIPI, or Parallel depending on your application.

- Board Size: Tailored to fit product dimensions.

- Resolution: From 0.3MP to 20MP depending on image detail needs.

- Field of View (FOV): Choose wide-angle or narrow FOV based on use case.

2. Choose the Right Components

- Sensor Chip: Sony, OmniVision, or Onsemi sensors for specific imaging needs.

- Lens Mount: S-Mount (M12), CS Mount, or fixed lens holder.

- IR Filter: IR-cut for daylight use or IR-pass for night vision.

- Connector: Pin headers, FPC cables, or USB interface board.

Not sure which sensor or lens combination is right for your application?

👉 Contact Us to start your custom camera module consultation.

3. Evaluate Annual Volume

Custom camera modules usually require a minimum order quantity (MOQ). If your Estimated Annual Usage (EAU) is over 500 units, custom development becomes feasible and cost-effective.

4. Testing & Integration

- Driver Support: Ensure compatibility with Windows, Linux, or Android.

- Firmware Tuning: Adjust white balance, exposure, gain, sharpness.

- Prototyping: Request evaluation samples to test integration.

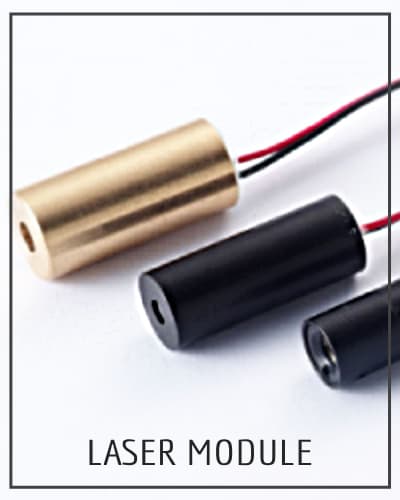

Custom Laser Modules: Diode Laser module, VCSEL Laser, Laser illumination, High Power Laser Head

Laser Modules Guideline introduces IADIY's laser module product line including RGB diode laser module, infrared laser module, line laser module, and customized diode laser module for convenient search and comparison by laser modules features list. You can open the laser modules guideline accordion to review the laser modules list and related laser diode module introduction and explanation.

More diode laser modules with different wavelengths and power options are available additionally to the standard laser diode module types. We also support the custom made laser modules as your requirements. Please send your requirements to us or leave the message in comment below. We'll reply to you soon!

IADIY provides standard laser modules that are convenient for quick and easy orders of samples or small quantities on our Online-store.

We also provide and welcome orders of custom made laser modules with any specification requirement. If you can not find the laser module that fits your application, please email your inquiries to sales@iadiy.com and briefly describe your requirements or applications to us. We will reply to you in a very short time (usually within two working days).

Laser Module Introduction

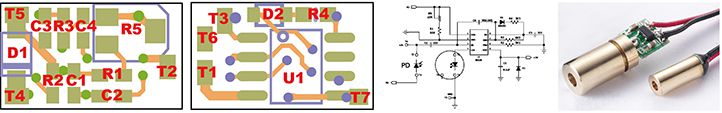

A "Laser Diode Module" usually comprises a laser diode, a driver circuit board, an optical lens (a laser collimator lens, a laser line generator or a laser pattern generating DOE (Diffractive Optical Element)) and mechanical parts. In high power laser modules, an additional TEC is also included for heat dissipation. The laser light emitting from the laser diode has a wide divergent span angle, therefore most applications require a laser collimator lens that will converge the laser light into a collimated laser beam. In the event of applications that would require a non collimated laser beam, IADIY also designs other complementary optical components to be assembled after the collimated laser beam, in order to achieve the desired pattern.

Another advantage of full laser diodes modules compared to single laser diodes is the presence of a specific driving circuit for the laser diode. Laser diodes are easily damaged components that need suitable working voltage and current supply in order to reach a stable output power, especially when considering the eye safety certifications.

Laser Diode Module Structure

- a laser diode

- an optical lens

- a laser driver circuit

- optical and mechanical properties

1. Laser diode:

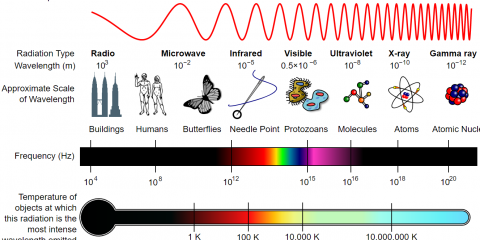

-Main characteristics of laser diode: wavelength, output power, operating temperature

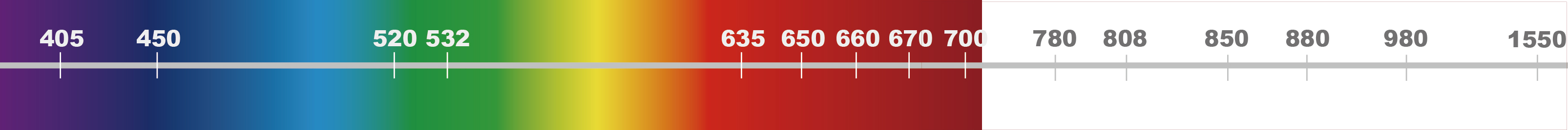

(Our laser diodes product list at https://www.iadiy.com/custom-laser-module, and other characteristics of laser diode like divergent angle, mode,and detsils please refer to the laser diode introduction. We can provide diode laser modules with wavelengths comprising 405nm, 450nm blue laser module, 520nm green laser module, 635nm, 650nm red laser module up to 1550nm infrared laser module and a laser module driving power can be equal or smaller than its laser diode operating power (as stated on the corresponding laser diode data-sheet).

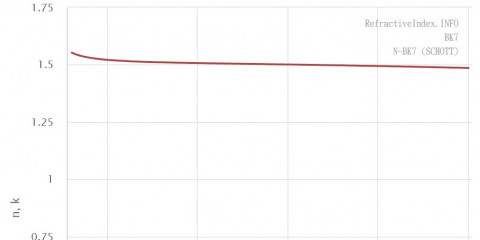

2. Optical Lens: Collimating Lens + Other Function Lens (Laser Line Generator, Laser Pattern Generator, or Special Feature Function Optical Components)

The following are the basic optical specifications that we need to agree upon before starting any laser module production.

- Main characteristics for the beam collimation: divergence angle, laser spot size.

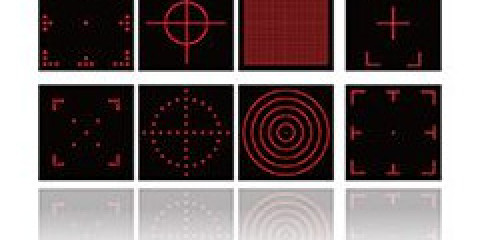

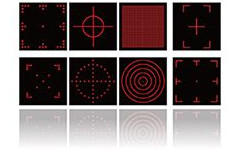

- Choice of the laser pattern: laser dot, laser line, laser cross line, or any kind of laser pattern achieved through using DOE (Diffractive Optical Elements).

Laser Collimating Lens, Laser Collimator Lens for Laser Collimation Beam

Usually the emitting laser light from the laser diode is divergent, and most applications need the laser beam as a straight light beam. Then it needs the collimating lens to focus the divergent laser light to a very small divergent angle we called laser collimation. The laser beam divergent angle, beam spot size, even laser line width or DOE laser pattern sharpness depend on the laser collimation performance. The collimating lens is the key for the collimated beam requirements. The collimating lenses selection you can refer to the Optical Lenses Store.

Laser Line Module / Laser Line Generator / Cross Line Laser Module properties:

The laser line module projects a span angle laser line pattern. The length of laser line depends on the span angle and the distance, longer as farther distance and bigger span angle. The standard span angle of IADIY line laser modules have 40°, 60°, 90°, 110° can be chosen. The standard line laser module series we only accept the different span angle customized no other special modifications. As the real applications most customers have the requirements for the laser line width, laser line central accuracy, laser line straight accuracy and the laser line power uniformity. Higher accuracy would cause much time for the line laser module alignment. Especial the requirement of laser power uniformity would consider using the different level laser line generator lens. If you have these requirements please take the reference of our high end line laser modules product line. And send your application and detail requirements to us. We’ll try to optimize your requirements to modify the line laser module as the most cost efficiency for your application.

-Main characteristics of line laser module: line laser span angle or the length, and laser line width, laser line straight (bend) accuracy at working distance, laser line power uniformity range, boresight requirements: central, tilt, rotation requirements.

※ For line lasers, specifications such as laser line width, laser line span angle, laser line uniformity, cross line center, mechanical requirements or original marking can be additionally modified.Our standard laser line module diameter is defined at 9mm but all dimensions can be adjusted according to your needs.

Laser Pattern Generator (DOE Laser Patterns)

You can check some of our available specific DOE laser patterns at our dedicated page for DOE: sales@iadiy.com

※ IADIY has the optical design capacity to design and create new optical components such as Laser Collimating Lens, Diffractive Optical Elements, etc.. according to your requirements. If you had any questions, please not hesitate to let us know.

3. Laser Driver Circuit:

The driving circuit of the laser modules can be either APC (Auto Power Control) or ACC (Auto Current Control). An APC driver controlled laser module will automatically adjust the input current in order to output a constant value of optical power. An ACC driver controlled laser module will in another way have a constant value of input current, while the output power may be a percentage variable by temperature change.

Apart from CW mode (continuous wave mode), our laser modules can be designed to input a TTL modulation if needed. It can be fixed to run at a certain frequency (Hz) or a specific duty cycle, or can it be alternated via an external PWM input. Most applications major concern the laser power for eye safety or laser sensing. It needs to consider a stable output laser power or to adjust the power for the application requirement. Usually we'll suggest the APC driving circuit for this kind application. Or you may need to add an external photo diode monitoring the power for the control. Because the laser diode emitting efficiency would vary as the temperature, environment and life time. You need to monitor the real output power just can keep it stable as you need. The driving current only for the reference can not exactly equal to the laser output power.

-Main characteristics of laser driver circuit: operating voltage range, CW or Pulse modulation mode (TTL/PWM signal control: frequency range), driving current requirements, APC or ACC mode, laser module safety or circuit protection requirements.

Laser Output Power

A laser output power can be measured with a Power meter. Lasers can work in CW mode (continuous mode) or in a pulsed mode. Pulses power can be accounted on the basis of their average power or on the peak power of each pulse. Average lasers power ranges from <1mW for laser pointers and other consumer products to several kW for laser cutting applications or laser weapon systems, etc.

In laser applications the laser power control is an important feature, which is why the laser modules usually need specific driving circuits. Also, the laser diodes output power is sensitive to the environment temperature. We usually regulate the laser modules through an APC control method (Automatic Power Control) for <5mW applications and for eye safety certification. Such circuit requires one photodiode to measure the laser output power and feedback it to the driver and adjust the current so as to achieve a stable output power range. Applications with pulse modulation can also be controlled in a stable average output power thanks to the photodiode feedback.

Another laser driver type uses the ACC control method (Automatic Current Control) which is used in higher power laser modules (>10mW) for applications that can bear larger power variation, but that may not suitable for eye safety certification.

IADIY also supplies laser modules with variable output power, which can be achieved through digital modulation or analog modulation control. Custom made design can also be prepared according to your requirements, don't hesitate to contact us at: sales@iadiy.com

4. Optical and mechanical properties:

The laser module casings can be designed into many shapes and with different materials, their surfaces can be treated for different operating environments like anodization for electrical isolation etc. Some differences in a laser module casing design might help to reach different operating temperatures as the heat sink to offer the best protection for the inner components. And there are some optical features are deigned and aligned by the mechanic structure like focal distance, boresight (coaxial tolerance), laser line features will increase the mechanical dimension size and complexities.

-Main characteristics for mechanical requirements: dimension requirements, boresight or called coaxial angel accuracy of laser module.

- [Optical Design Manufacturing Service - Optics and Photonic Elecro-optical Development ]

- [Laser Pattern - DOE, HOE and Diffusers ]

- [Glass Molded Aspheric Lenses ]

- [Moded Plastic Asphric Lenses]

- [Optical Coating Filter]

- [Optical, Photonic, Optoelectronic Systems and Solutions Development ]

- [Optics, Photonics, Optoelectronics Products Design Manufacturing ]

- [Optical Mechanics, Precision Mechanical Parts, Optoelectronic Modules Assembly ]

Optical

Design Manufacturing Service - Optics and Photonic Elecro-optical

Development

Our

manufacturing facilities provide optics and product design services and

contractual manufacturing of photonic electro-optical subsystems,

complex laser and optical systems. We disposes of an unsurpassed design

and development capacity, comprising an in-house optics division, an

integrated circuit design division and an optical, mechanical and

electrical integration division making us the ideal choice for clients

who wish to outsource crucial designs and manufacturing

responsibilities to a highly qualified and trusted partner.

Laser

Pattern - DOE, HOE and Diffusers

We

offer custom design service with high performances to support your

needs for specific laser patterns. DOE, HOE and Diffusers designs for

complex laser patterns or diffraction spots precise manipulation are

achieved through our computational design methods and wafer-based

technology

Glass

Molded Aspheric Lenses

The

glass molded aspherical lenses are not only able to correct aberrations

through one singlet lens but also display a smaller size, higher

performances, and ensure a more stable quality control in during mass

production compared to the traditional ground lenses. Thanks to a state

of art Precision Glass Molding (PGM) technology, we provide glass

molded aspherical lenses with:

• Competitive

cost

• Good quality

• Fast delivery

• Optical design and simulation

• In-process testing and machine inspection

...More

Moded

Plastic Asphric Lenses

Our

plastic molded aspheric lenses were designed for laser and spherical

aberration elimination with high light-gathering, efficiency in

condensing, high power, high precision, and high environment

reliability required applications.

We have an extensive experience in developing excellent manufacturing process of plastic molded aspheric lens, in designing and offering cost-effective optical solutions for your individual demands.

SERVICES & CAPABILITIES:

• Optical design and support

• Rapid prototype

• Fast and dependable volume production at affordable price

...More

Optical Coating Filter

Our

custom optical coating services with precision optical coating

technology are available to support all your applications in

Fluorescence microscopy, Spectroscopy, wavelength selectors and other

related optical fields. Our coating services includes anti-reflective

coating, beam-splitter coatings, filter coatings, high-reflector

coatings, reducing internal and external surface reflection through

single-layer to broadband multilayer coatings. Other types of coating

are also available upon customers’ requirement.

SERVICES & CAPABILITIES:

• Optical design and optical coatings

• Short lead time

• Constant quality at top-level

• In-house tool design and manufacture

...More

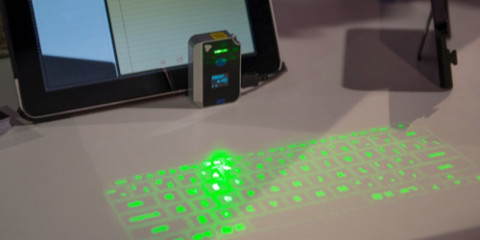

Optical, Photonic, Optoelectronic Systems and Solutions Development

With

decades of experience in laser technology, optics, semiconductors,

electronics, precision molding and mechanics, Our engineering

facilities have specialized in designing and developing complex

optoelectronic systems, making us a trustworthy partner for our clients

who are seeking for high-performance designs and precision

manufacturing capabilities. Our product range includes: virtual

keyboards, laser range finders, and laser scanning systems

SERVICES & CAPABILITIES:

• System analysis

• Feasibility evaluation

• Optical, mechanical and electronic design

• Prototype design and fabrication

...More

Optics, Photonics, Optoelectronics Products Design Manufacturing

In

addition to strong capabilities in offering system development

services, we also provides services for complex in-house assemblies of

photonic electro-optical systems which maintain outstanding product

quality standards. We have a wealth of practical experience of in

supplying components, sourcing on your behalf, or managing a supply

chain with your suppliers to meet your requirement for volume

production.

SERVICES & CAPABILITIES:

• Optical design and coating

• Tooling, fixture design and manufacturing

• From prototype to volume production

• Outsourcing management

• Assembly services

• Quality and reliability system set up

...More

Optical Mechanics, Precision Mechanical Parts, Optoelectronic Modules Assembly

Our

molding services combine with our hard tooling solutions perfectly. Our

molds are manufactured using a state-of-the-art processing technology

that offers to our customers to a rapid process to prototyping e,

bridging, and short production runs, and that allows us to produce

molds with cost control to for low volume production runs.

SERVICES & CAPABILITIES:

• Rapid tooling

• Customers own the injection mold

• Proven quality

• From prototype to production

...More